Polymer Systems

BROCHURE

Polymer selection is one of the most important decisions in assuring the proper

performance of any belt filter press. Charter offers sludge sample testing to assist

toward that goal.

One size does not fit all.

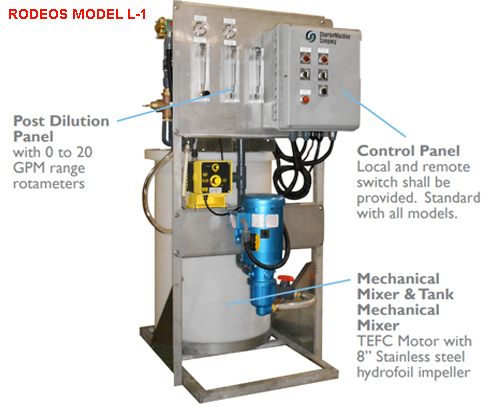

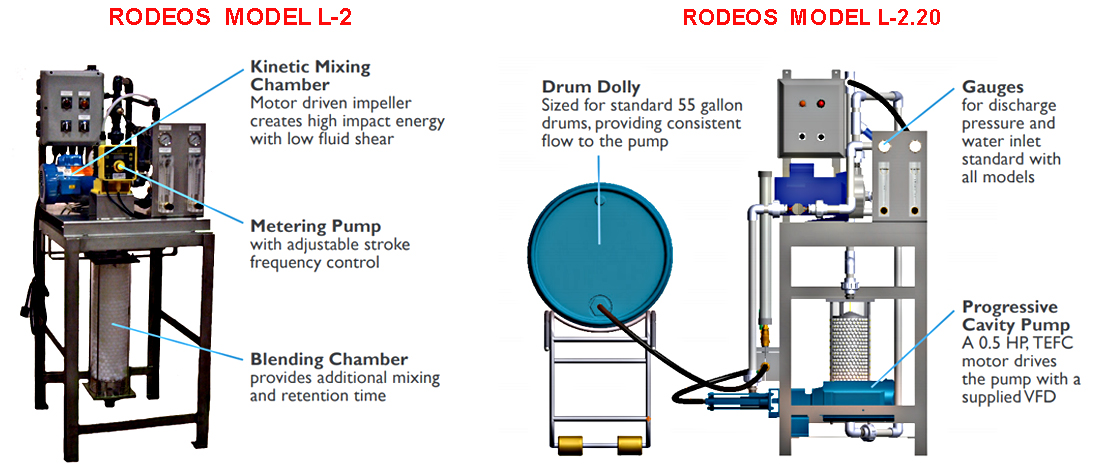

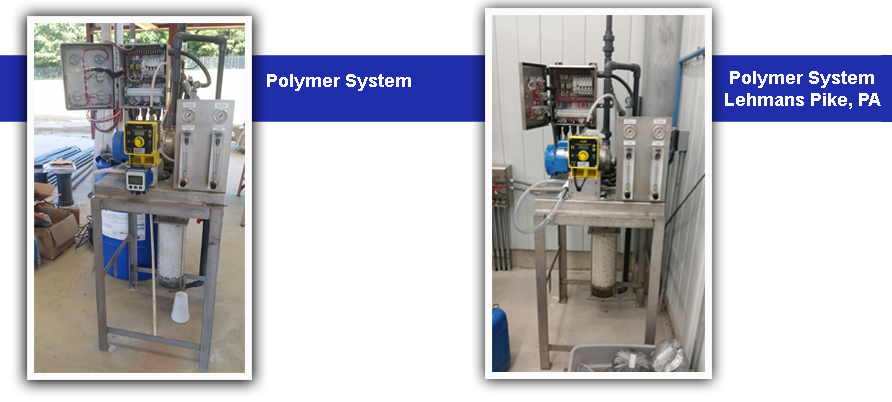

Charter Machine Company offers both dry and emulsion polymer systems. Our most popular

units are the L-1 system (shown) and the L-2 system, which are utilized with emulsion

polymers. The range of polymer systems necessary to accommodate every facility’s

application is lengthy. Charter can design and customize the polymer system to meet any

clients requirements.

Organic flocculants (also called polyelectrolytes or polymers) are used to aid in the settling of solids and thickening of dewatering of sludge. There are dry, emulsion and liquid (e.g. mannich) types of polymers. Polymer solutions must be properly prepared and aged so that the polymers achieve their full potential by unfolding their long molecular chains. Aging is required for emulsion polymers and especially important for dry polymers. Improperly prepared or insufficiently aged polymer solutions result in higher polymer consumption and costs.

Capacities

The range of polymer systems necessary to accommodate every facility's application is lengthy. Charter can design and customize the polymer system to meet any client's requirements

|

Polymer System

|

Mixing/Holding Capacity Gallons

|

Type of Polymer

|

||

|

Liquid

|

Emulsion

|

Dry

|

||

| Roedos L-2 Automatic |

Variable | x | ||

|

Roedos L-I

Automatic |

50

|

.

|

x

|

.

|

|

Roedos III

Automatic |

300/450

|

x

|

x

|

x

|

|

Roedos VI

Automatic |

600/750

|

x

|

x

|

x

|

|

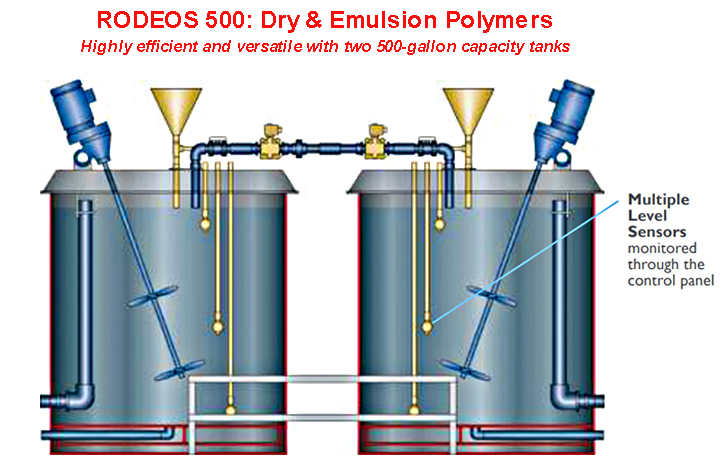

Roedos 500

|

500/500

|

x

|

x

|

x

|

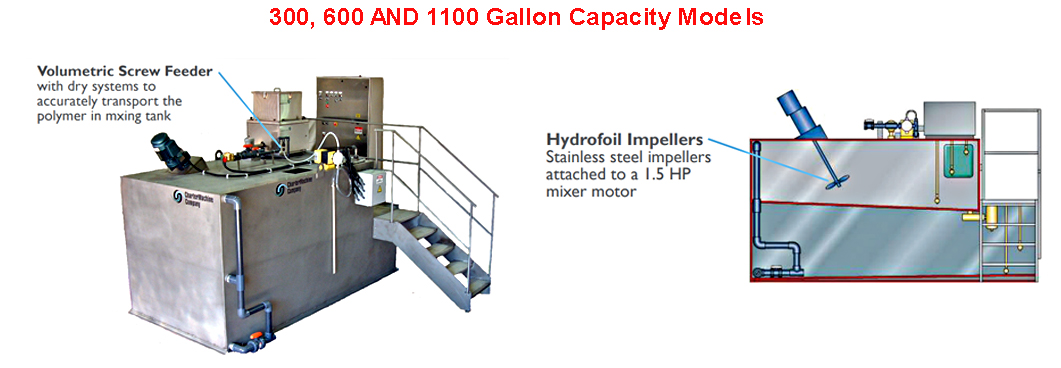

ROEDOS III, VI, 500

Our ROEDOS systems provide for sufficient aging time while ensuring that sufficient polymer solution is always available to allow adjustments of your process requirements.

Our ROEDOS systems utilize variable speed progressive cavity type pumps to inject the polymer solution into the water or sludge stream. We do not rely on the incoming water pressure that can vary or be too low to properly prepare and transport the polymer solution into the water or sludge line.

Our ROEDOS systems maintain a constant dosing rate independent of pressure variations in either the water or sludge line.

The polymer solution is pumped into the sludge line through our multi-port injection ring.

Polymer solution and sludge are rapidly mixed in our inline mixer. Mixing energy is easily adjustable.

Non-corrosive construction (stainless steel base and vessels, Sch 80 PVC piping)

We provide a full range of customer services by our team of trained service technicians.

|

|

|

.jpg)