Lime Post Treatment

When it comes to sludge, dryer is better; and that is precisely what the Charter Machine Company Lime Post Treatment Modules achieve. By adding an alkaline additive or kiln dust to sludge after initial processing, the Lime Post Treatment Modules further de-waters it, creating a dry, crumbly lime-slude mixture that will not clog equipment and is easy to haul and land fills or spread on farm land.

When it comes to sludge, dryer is better; and that is precisely what the Charter Machine Company Lime Post Treatment Modules achieve. By adding an alkaline additive or kiln dust to sludge after initial processing, the Lime Post Treatment Modules further de-waters it, creating a dry, crumbly lime-slude mixture that will not clog equipment and is easy to haul and land fills or spread on farm land.

Lose water, save money

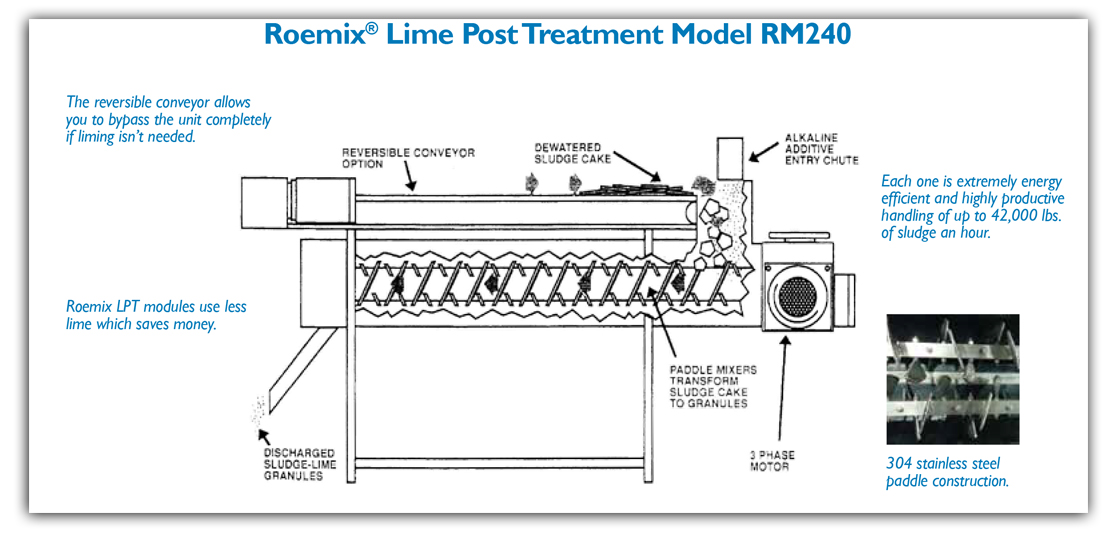

The Lime Post Treatment Modules saves money by using less lime than comparable treatment. Plus its reversible converyor allows you to by-pass the unit completely if it is not needed. The RM450 Lime Post Treatment Module can handle 42,000 pounds of sludge per hour.

By addition of quicklime to dewatered sludge cake, a stabilized and/or disinfected biosolids can be produced. Our systems are used:

• For Alkaline Sludge Stabilization (Class B)

• For Alkaline Sludge Disinfection (Class A)

Features and Benefits

- Uses less lime than other lime treatment methods.

- Reversible conveyor lets you feed into or bypass the unit.

- High productivity- the LPT can handleup to 42,000 lbs. of sludge per hour.

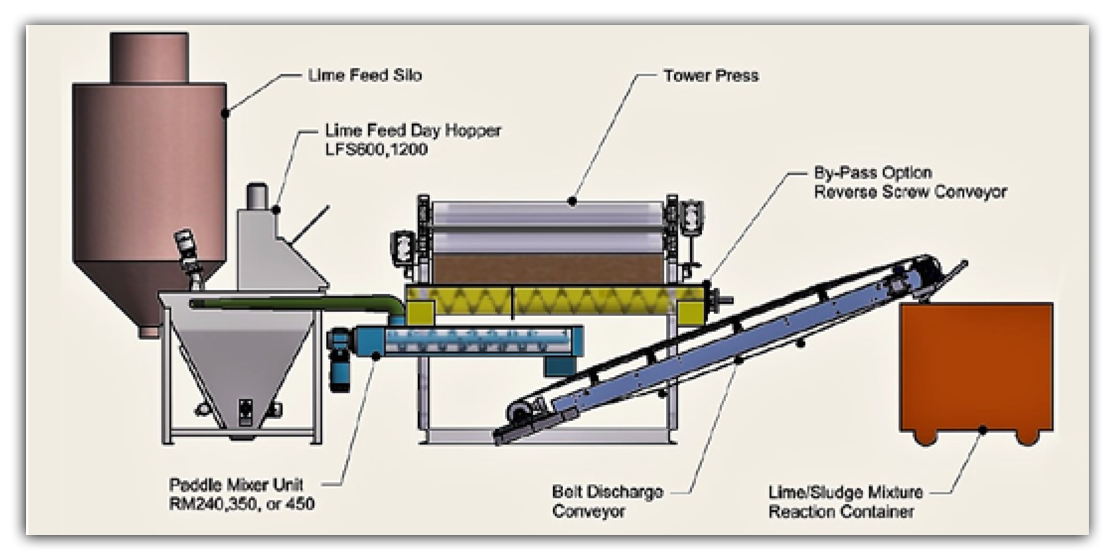

- Can be used in tandem with any dewatering equipment, including vacuum filters, centrifuges and belt filter presses.

- Extremely energy efficient.

- End product is PSRP and PFRP approved.

Charter's Assistance

- Complimentary Design Assistance by Experienced Engineers

- Detailed Engineering

- Delivery of Components, e.g. Pug Mills, Lime Feed Silos (LFS) and Lime Systems, Air Scrubbers

- Assistance during Installation, Start-up and Trouble-shooting

- Operator Training

- Outstanding Warranty for Components and Engineering

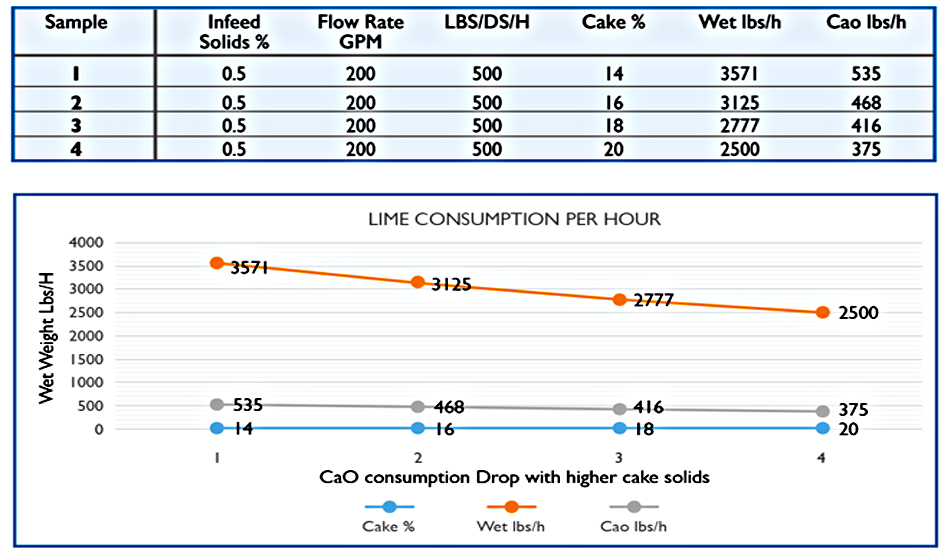

charts

Lime Post Treatment Modules can be added to existing equipment at current facilities.| SPECIFICATIONS | RM150 | RM240 | RM350 | RM450 | |

| Roediger Lime Post-Treatment Module (LPT) Maximum capacityrange, lbs. of sludge per hour |

2,000 to 8,000 |

3,000 to 12,000 |

8,000 to 25,000 |

14,000 to 42,000 |

|

| LPT Mixer Dimensions* length, overall (feet) width, overall (feet) height (feet) variable |

7.2 2.4 1.7 |

9.3 3.0 2.0 |

9.3 3.5 2.5 |

9.3 4.0 2.9 |

|

| Electrical Power Requirements Mixer (hp) Reversible conveyor (hp) |

3.0 0.75 |

5.0 0.75 |

7.5 1.0 |

10.0 1.0 |

|

*Dimensions vary with different drive models and optional supports.

Model LFS 600 and 1200

Model LFS 600 and 1200

and 1200Optional Loading Platform

The optional loading platform and steps are made of carbon steel treadplate. Railings protect both sides of the steps and all of the platform except stair access and bag dump access. Platform height and orientation shall allow comfortable access to the bag shelf. All platforms, steps, and railings if required shall comply with OSHA standards.

Optional Dust Collector

Optional Dust CollectorDust collector shall be glange mounted to the hopper body and shall return collected dust to process without secondary handling, contamination, or waste. Filtered air shall vent to work area. cleaning cycle shall be automatically controlled by a solid state timer in a factory mounted NEMA 12 enclousure. The until shall have a hinged access door for visual inspection of filter bags. The jet pipe and filter tube shall be capable of individual removal. Drive shall be 1 HP AC. the dust collector will require a minimum of 3/4" air connection.

.jpg)